| Air Supply Mode | Front / Side |

| Power Supply | 380V 3Ph - 50Hz |

| Fan Section | ZIEHL-ABEGG EC Fan |

| Humidifier Section | CAREL Electrode Type |

Chilled Water In-Row Cooling System

Features

Specifications

Applications

Download

-

• Advanced Controller

Our system features an advanced controller with remarkable teamwork functionality. It can support up to 16 remote temperature/humidity sensors. Equipped with a standard RS485 communication interface, it also offers optional SNMP and TCP/IP interfaces, ensuring seamless integration with various monitoring and control systems.

• Efficient EC Fan System

Energy – Saving: Compared to traditional AC motors, our EC fan system saves 20% – 30% of energy. It comes with a soft – startup function, minimizing the startup current.

Intelligent Adjustment: The fans can automatically adjust their rotational speed based on cooling requirements and airflow pressure, providing the necessary airflow.

Reliability: With an N + 1 redundancy configuration, the fan system ensures continuous airflow even if any fan fails. Additionally, it’s designed for easy maintenance.

• High-Efficiency Compressor System

Our compressor system uses R410A refrigerant and adopts an inverter compressor. This type of compressor is known for its high reliability and excellent energy-efficiency ratio, delivering stable and efficient performance.

• Electronic Expansion Valve

Energy-Saving and Precise Control: The electronic expansion valve smoothly adjusts the valve throttle, effectively saving energy. It operates over a wide range, reducing the superheat degree and improving the Energy Efficiency Ratio (EER).

Fast Response: It enables precise matching between cooling capacity and heat load, achieving accurate cooling with a quick response.

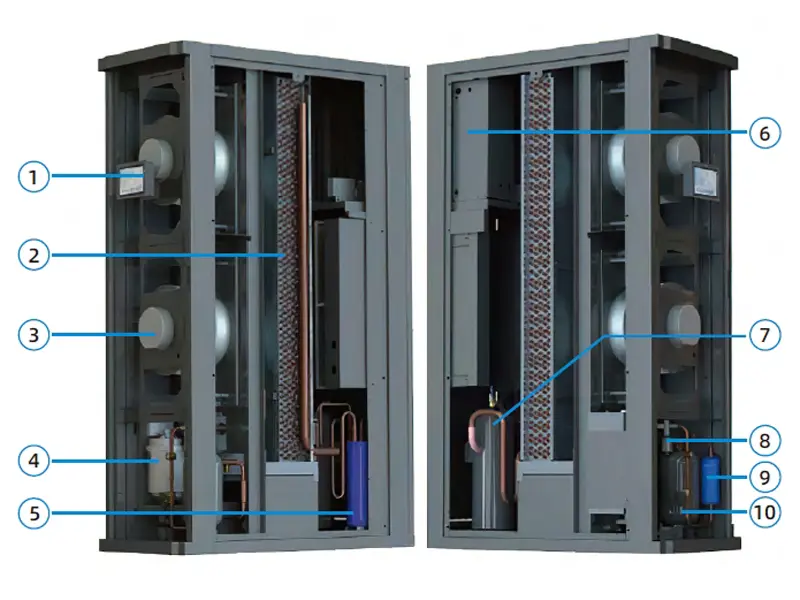

① – Control system device ② – Steam hair device ③ – High effect EC FAN ④ – Humidifier ⑤ – Oil separator ⑥ – Frequency converter ⑦ – Inverter compressor ⑧ – Electronic expansion valve ⑨ – Drying filter ⑩ – Liquid storage tank Read More -

Unit 025RC 045RC 065RC Water Temperature inlet/outlet - ℃ 7/12 10/15 13/18 7/12 10/15 13/18 7/12 10/15 13/18 Total Capacity – kW (45℃/12%RH Return Air) 47.1 43.2 39.3 76.0 69.6 63.2 107.6 98.6 89.6 Sensible Capacity –kW (45℃/12%RH Return Air) 47.1 43.2 39.3 76.0 69.6 63.2 107.6 98.6 89.6 Total Capacity –kW (40℃/18% Return Air) 41.0 36.8 32.9 65.4 59.0 52.4 93.2 84.0 74.8 Sensible Capacity –kW (40℃/18% Return Air) 40.8 36.8 32.9 65.4 59.0 52.4 93.0 84.0 74.8 Total Capacity –kW (37℃/24% Return Air) 38.8 33.0 28.9 59.8 52.4 46.0 87.0 75.0 65.8 Sensible Capacity –kW (37℃/24% Return Air) 36.3 33.0 28.9 59.2 52.4 46.0 83.2 75.0 65.8 Total Capacity –kW (35℃/26%RH Return Air) 35.9 30.3 26.3 55.4 48.2 41.6 80.4 69.0 59.6 Sensible Capacity –kW (35℃/26%RH Return Air) 33.8 30.3 26.3 54.8 48.2 41.6 77.4 69.0 59.6 Total Capacity –kW (32℃/30%RH Return Air) 31.7 26.3 22.2 48.4 41.4 34.8 71.0 59.8 50.4 Sensible Capacity –kW (32℃/30%RH Return Air) 29.9 26.3 22.2 48.2 41.4 34.8 68.2 59.8 50.4 Total Capacity –kW (30℃/34%RH Return Air) 29.1 23.6 19.5 44.4 37.0 30.4 65.4 53.6 44.2 Sensible Capacity –kW (30℃/34%RH Return Air) 27.1 23.6 19.5 43.6 37.0 30.4 62.0 53.6 44.2 Air Volume -m3/h 4800 9000 11400 Mount Type Row Row Row Height –mm 2000(42U) 2000(42U) 2000(42U) Depth –mm 1100 1100 1100 Width –mm 300 600 600 Weight –kg 190 330 400 Reheat-kW 3 3 3 Hum.(optional) -kg/h 1.5 1.5 1.5 Power Input 1) 208-240V/50-60Hz/1Ph-2Ph 380-415V/50-60Hz/3Ph 380-415V/50-60Hz/3Ph FLA –A1)with heating 22.7 13.7 16 FLA –A1)with hum. 28 19 26 Power Input 2) - 200-230V/50-60Hz/3Ph 200-230V/50-60Hz/3Ph FLA –A2)with heating - 25 29 FLA –A2)with hum. - 28.1 35.5 Power Input 3) - 460V/50-60Hz/3Ph 460V/50-60Hz/3Ph FLA –A3)with heating - 11.3 13.2 FLA –A3)with hum. - 16 22 Read More -

-

High-density Cabinet area in the Data Center: The inter-row precision air conditioner can directly deliver cold air to the air inlet of the cabinet, which is highly matched with the airflow organization of the cabinet, and can effectively solve the heat dissipation problem of the high-density cabinet, ensuring that the equipment operates in a suitable temperature environment.

-

Computer Room with High Cooling Efficiency: The inter-row precision air conditioner is close to the cabinet, shortening the transmission distance of the cold air, reducing the air duct loss, and can quickly and accurately control the temperature and humidity in the computer room. It has high cooling efficiency and is suitable for environments with strict requirements on cooling effect and response speed.

Read More -

-

Read More

Contact Us

Reach Out for Product and Technical Support