¿Qué tipo de producto eres?

¿Buscando?

-

Soluciones para centros de datos

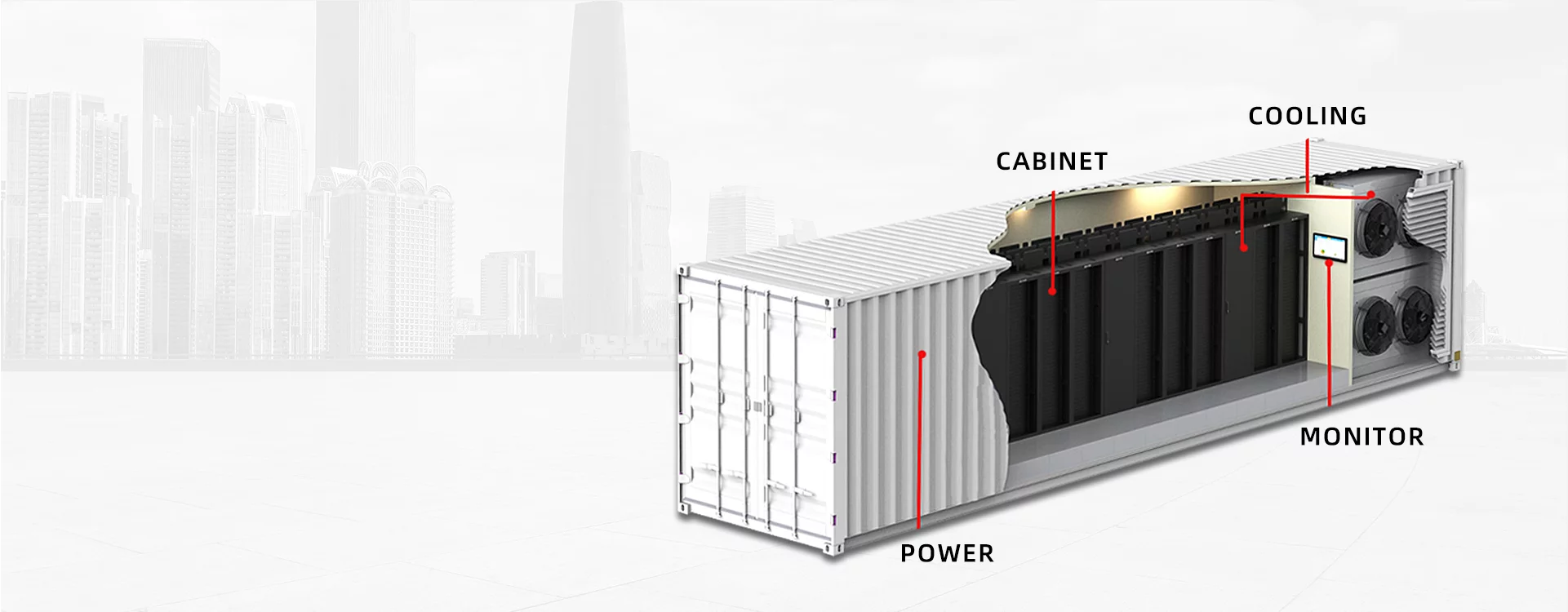

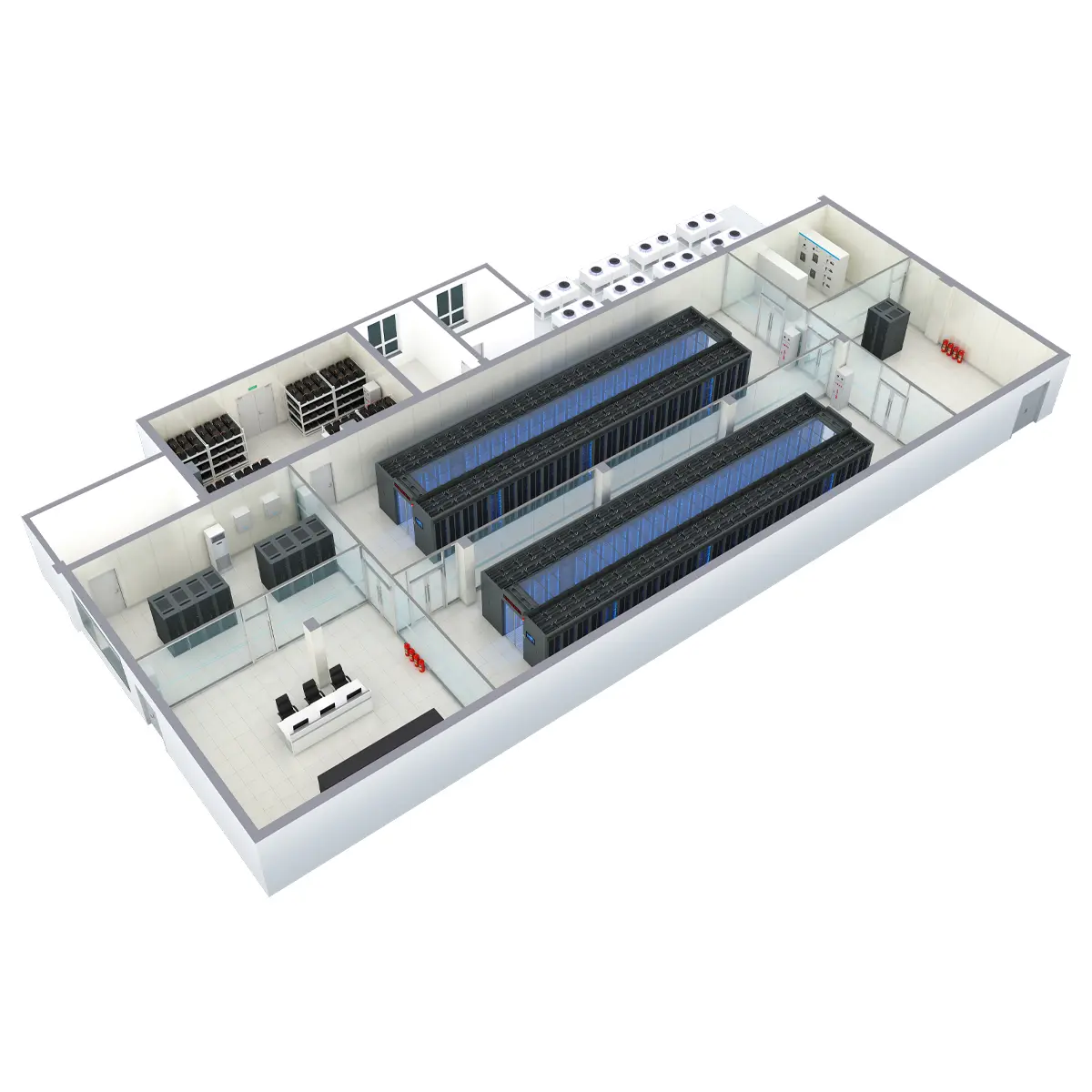

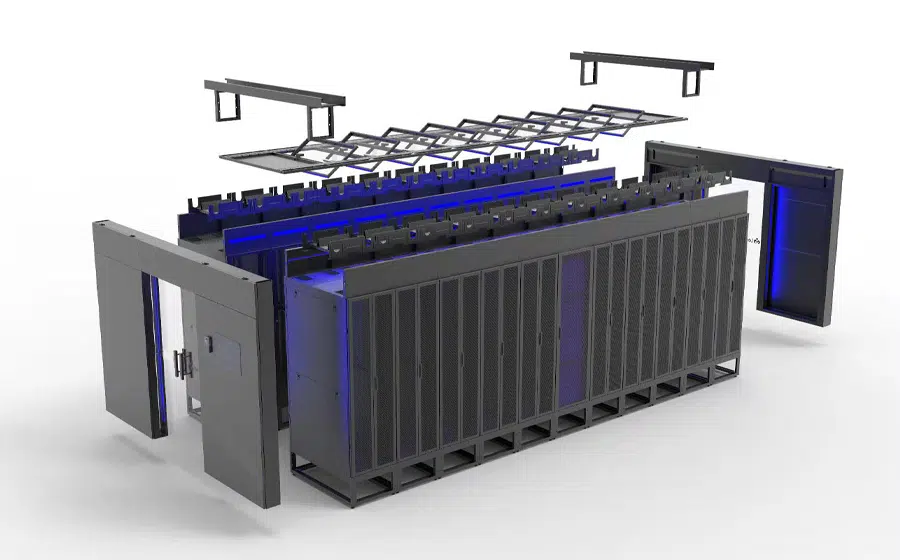

· El centro de datos modular es un diseño de sistema integrado que abarca energía, refrigeración, red, seguridad, monitoreo y distribución del espacio. Su objetivo es proporcionar un entorno operativo estable, eficiente, seguro y sostenible para los centros de datos, asegurando que el equipo de procesamiento y almacenamiento de datos funcione de manera óptima, satisfaciendo las necesidades de los clientes en materia de computación, almacenamiento, transmisión y administración de datos. · La solución de centro de datos modular integra varias tecnologías y equipos. A través de la planificación científica y la integración, sus componentes se combinan orgánicamente para formar un todo colaborativo.Ver más

-

Enfriamiento crítico

El aire acondicionado de precisión es un equipo profesional de control ambiental que regula con precisión la temperatura, la humedad, la limpieza y la distribución del aire. Se utiliza principalmente en lugares con requisitos ambientales exigentes, como centros de datos, salas de máquinas de comunicaciones, instalaciones médicas, laboratorios y objetos de colección. Según la ubicación de instalación, se clasifican en: desde la distancia hasta la proximidad de la fuente de calor, a nivel de sala, en fila y en rack. Refrigeran toda la sala, las filas de equipos y los puntos de acceso locales, respectivamente. La solución de refrigeración líquida ofrece mayor disipación de calor y eficiencia energética. El sistema de refrigeración para telecomunicaciones es un sistema integrado para armarios eléctricos de telecomunicaciones exteriores.Ver más

-

Poder crítico

· La energía crítica desempeña un papel fundamental para garantizar el funcionamiento continuo, estable y seguro de un sistema o equipo específico. Por lo general, presenta una alta confiabilidad, estabilidad y capacidad de suministro de energía continua. Es la piedra angular para garantizar el funcionamiento normal de la infraestructura crítica. · La energía crítica puede ser un equipo de energía independiente o un sistema de energía complejo, que consta de un sistema de suministro de energía ininterrumpido, distribución de energía, sistema de barras y conductos, conmutación inteligente, etc.Ver más

-

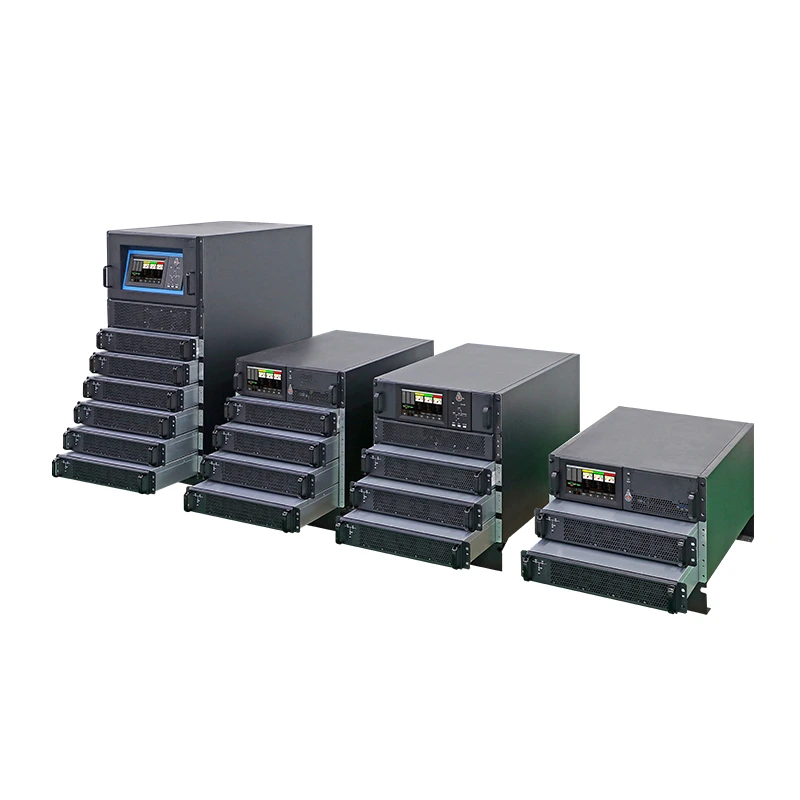

Fuente de alimentación UPS

El Sistema de Alimentación Ininterrumpida (SAI) está diseñado para proporcionar alimentación continua a los equipos en caso de interrupción o anomalía de la red eléctrica. Cuando la red eléctrica es normal, el SAI estabiliza y filtra la energía, eliminando picos de tensión, sobretensiones y otras interferencias. En caso de fallo de la red eléctrica, la corriente continua (CC) de la batería se suministra continuamente al equipo a través del inversor para garantizar su funcionamiento normal. Clasificamos los SAI en alta frecuencia (torre y montaje en rack), frecuencia industrial, modulares e interactivos en línea según sus principios de funcionamiento, modos de operación y formas estructurales. Elija diferentes capacidades y tipos según sus necesidades.Ver más

-

Fuente de alimentación para telecomunicaciones

La fuente de alimentación para telecomunicaciones, una infraestructura esencial para garantizar el funcionamiento estable de los equipos de telecomunicaciones, consta de rectificadores, controladores, sistemas de refrigeración, armarios, etc. Las fuentes de alimentación para telecomunicaciones de exterior ofrecen una salida de CC estable; la fuente de alimentación 5G se adapta a las altas demandas de potencia de los dispositivos 5G; la fuente de alimentación híbrida combina las ventajas de la energía solar y la red eléctrica. Todo esto garantiza una alimentación fiable para los equipos de las industrias de telecomunicaciones.Ver más

-

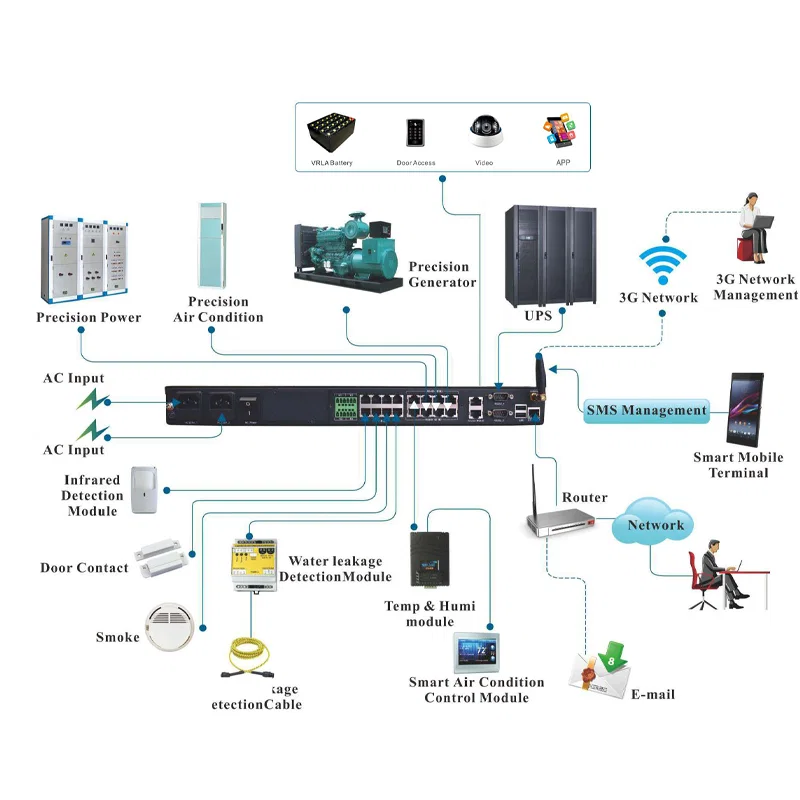

Cerramientos y gestión

· El gabinete del centro de datos es un gabinete de metal estándar para instalar hardware central como servidores, equipos de almacenamiento y equipos de red. Su altura se mide en unidades "U" con varias especificaciones. Proporciona protección física, uso eficiente del espacio y gestión de la disipación de calor. Como parte crucial de la infraestructura del centro de datos, se utiliza para colocar y administrar de forma centralizada el equipo. · El sistema DCIM (Gestión de la infraestructura del centro de datos) es una plataforma de software dedicada a la gestión de la infraestructura del centro de datos. Al recopilar, integrar y analizar datos de varios equipos y sistemas en el centro de datos, incluidos los gabinetes y sus equipos, los sistemas de energía y los sistemas de enfriamiento, permite funciones como la gestión de equipos y el seguimiento de activos, la gestión de la energía, el monitoreo ambiental y la planificación y optimización de la capacidad. Unifica la gestión de los centros de datos modernos, que cuentan con numerosos dispositivos y sistemas complejos, mejora la eficiencia de la gestión y la calidad operativa de los centros de datos.Ver más

Sobre nosotros

Hefei Shuyi Digital Power Co., Ltd.

-

11 +

años

Experiencia en la industria

-

80 +

cooperar

Vendido a más de 80 países

-

400 +

fogonadura

Por todo el país

-

20000 +

Área del parque industrial (㎡)

Fábricas de más de 20.000 metros cuadrados

Liderando el camino en infraestructura de centros de datos: su socio de confianza

En el ámbito de los centros de datos, la infraestructura crítica circundante es crucial. Nuestra empresa, aprovechando sus puntos fuertes, aspira a ser líder en el sector y construye una base sólida para los proyectos de centros de datos de sus clientes.

-

Fuerte integración

-

Servicios de extremo a extremo

-

Personalización flexible

-

Eficiencia rápida

-

Nuestro equipo se destaca en la integración de soluciones para centros de datos, sistemas de refrigeración, monitoreo y suministro de energía. Con nuestra plataforma de gestión inteligente, cada sistema trabaja en conjunto para estabilizar el entorno del servidor, lo que reduce los costos y mejora la confiabilidad.

-

Brindamos soporte durante todo el ciclo de vida del centro de datos, desde la planificación del sitio y la elección de equipos hasta la instalación y el mantenimiento. Brindamos monitoreo remoto las 24 horas, los 7 días de la semana, resolución rápida de problemas y mantenimiento predictivo. Los informes periódicos, la capacitación y los conocimientos mejoran aún más las operaciones del cliente.

-

Ofrecemos una amplia gama de soluciones de infraestructura escalables, desde unidades compactas para centros de datos de borde hasta sistemas redundantes para centros financieros. Las opciones estándar o personalizables satisfacen diversas necesidades comerciales, incluido el almacenamiento de energía y las integraciones de comunicaciones avanzadas.

-

Priorizamos la puntualidad, respondemos las consultas en un plazo de 24 horas y aceleramos el diseño y la entrega de soluciones. Los flujos de trabajo eficientes, las alianzas sólidas y la gestión inteligente garantizan una ejecución rápida y una entrega confiable del proyecto, incluso para necesidades urgentes.

Noticias y perspectivas

-

-

2025.12.26

2025.12.26Saludando a los luchadores, avanzando: la conferencia del proyecto "Campaña de baterías de litio" de Soeteck concluye con éxito

En diciembre de 2025, Hefei Soeteck Technology Co., Ltd. celebró la Conferencia de Resumen y Reconocimiento del Proyecto "Campaña de Baterías de Litio", con Hefei Zhongjiyuan Technology Co., Ltd. como socio colaborador. Centrada en la revisión de los logros...

Ver más -

2025.11.19

2025.11.19Una delegación de Libia visita Soeteck y reconoce las soluciones de centros de datos.

Recientemente, una delegación de Libia visitó Soeteck para realizar una inspección in situ e intercambiar información en profundidad sobre soluciones para centros de datos, sentando las bases para la futura cooperación entre ambas partes. La delegación llegó primero a las instalaciones de Soeteck...

Ver más -

2025.05.29

2025.05.29Inspección del proyecto del centro de datos de contenedores de Qatar

Soeteck recibió recientemente a una delegación de su cliente catarí de centros de datos de contenedores para una revisión in situ del progreso del proyecto de centro de datos modular personalizado de 40 pies. La solución está diseñada para satisfacer las necesidades de infraestructura crítica del cliente...

Ver más

-

-

-

2026.01.04

2026.01.04Soluciones integrales para contenedores refrigerados por líquido: cómo afrontar los desafíos de las densidades de potencia ultraaltas

Comprender la necesidad de refrigeración líquidaLas ventajas de las soluciones integradasComponentes clave de los contenedores refrigerados por líquido integradosAplicaciones de los contenedores refrigerados por líquido integradosConclusión¿Cuáles son los beneficios de utilizar refrigeración líquida...

Ver más -

2025.12.31

2025.12.31Aire acondicionado de precisión refrigerado por líquido: elimine los problemas de refrigeración del centro de datos

Problemas principales resueltos con aire acondicionado de precisión refrigerado por líquido Adaptación a cargas de calor elevadas: supere los cuellos de botella en el enfriamiento por aire Con una potencia de servidor único que supera los 3 kW y una densidad de gabinetes que alcanza los 200 kW+, los aires acondicionados de precisión refrigerados por líquido tradicionales...

Ver más -

2025.12.30

2025.12.30Fuente de alimentación para telecomunicaciones en exteriores: solucione sus problemas de energía en campo

Las temperaturas extremas, los frecuentes cortes de energía y los altos costos de mantenimiento afectan la cobertura de su red. No permita que un suministro eléctrico inestable frene sus operaciones de telecomunicaciones. Nuestra fuente de alimentación para telecomunicaciones en exteriores está diseñada para afrontar...

Ver más

-

-

-

2025.04.09

2025.04.09ENERGÍA EN ORIENTE MEDIO 2025

Soeteck participó activamente en Middle East Energy 2025, un evento clave en el sector energético. El director general de la compañía, acompañado por parte del equipo técnico de ventas, asistió a esta feria. Middle East Energy 2025 tuvo lugar del...

Ver más -

2024.11.20

2024.11.20Cairo ICT'24: Presentación de soluciones energéticas digitales

20 de noviembre de 2024, El Cairo, Egipto — En Cairo ICT'24, SHUYI DIGITAL POWER presentó soluciones innovadoras diseñadas para satisfacer las crecientes demandas de energía digital de Medio Oriente y África. El evento brindó una plataforma para interactuar con re...

Ver más -

2024.09.12

2024.09.12La reconocida empresa estadounidense de soluciones de TI elogia los productos de Soeteck

En mayo de 2024, clientes de Estados Unidos visitaron la fábrica de SHUYI. Durante este viaje, recorrieron en profundidad varios talleres, como el taller de chapa metálica, el taller de evaporadores y condensadores, el taller de pintura y el taller de ensamblaje...

Ver más

-

Caso

-

Ministerio de Educación de Ghana Pasillo frío

-

Proyecto de pasillo frío del MDC del Banco de Zambia

-

Pasillo frío de la empresa IDC de Serbia

-

Proyecto de sala de informática de Mauritania Telecom

-

Proyecto Mongolia Sinus Dochi LLC

-

Proyecto de la Compañía de Telecomunicaciones de FIJI

-

Proyecto de recuperación ante desastres en Oriente Medio

-

Pasillo frío en Tailandia para proyecto bancario

Fogonadura

Atienda a clientes globales y conviértase en un experto líder en infraestructura de energía digital.