Soeteck Room-level Precision Air Conditioning

Release time: 2025-05-27

From Basic Cooling to Intelligent Temperature Control

Room level precision air conditioning has a similar appearance to ordinary air conditioning, but their application scenarios are vastly different. Designed specifically for data centers, laboratories, and other critical environments, they offer ±1°C temperature accuracy, 24/7 continuous operation, and advanced filtration, serving as industrial-grade thermal management solutions for equipment stability.

Diversified Cooling Technologies

Air Cooling (AC)

- Advantages: Flexible deployment, ideal for small-to-medium power scenarios (e.g., 7.5–27.5kW per cabinet), supporting upflow and downflow airflow configurations.

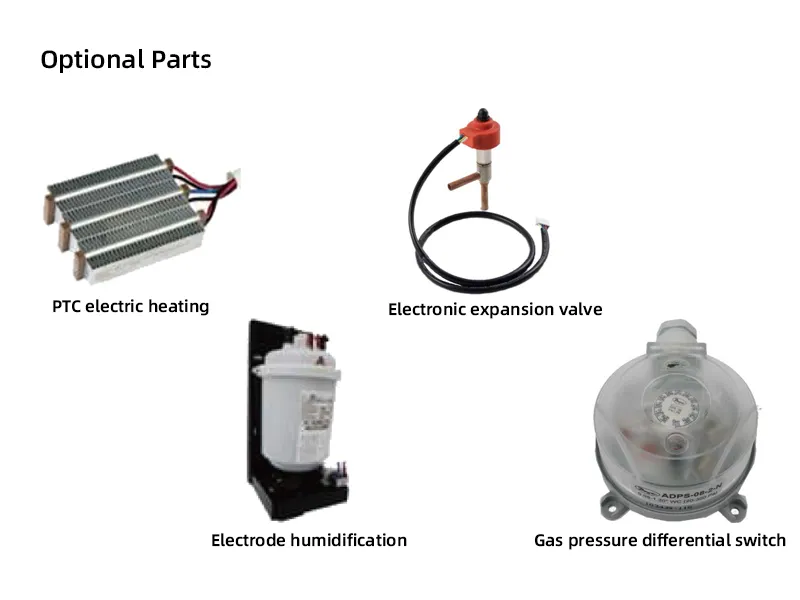

- Example Product: SYRC MA Series, featuring PTC electric heating and electrode humidifiers, with ±1°C temperature control and ±5% RH humidity precision, suitable for small-to-medium server rooms.

Liquid Cooling (CW/DX)

- Direct Expansion (DX) Cooling: Uses refrigerant for direct heat exchange, eliminating the need for chilled water systems while integrating with existing AC infrastructure. CDU solutions combine liquid and air cooling, enabling up to 130kW heat dissipation per cabinet.

- Chilled Water (CW) Cooling: Leverages water circulation for high-capacity heat removal (e.g., SYRC DC Series with up to 233.4kW cooling capacity), ideal for large-scale data centers.

Free Cooling (Natural Cooling)

- Utilizes low outdoor temperatures or glycol-based heat exchangers to reduce compressor energy consumption. For instance, the SY Series with glycol-free cooling modules achieves PUE below 1.2 in colder regions (e.g., Northern Europe, Northwest China).

Core Component Advancements

- Compressor: High-efficiency scroll compressors with EC inverter modulation (10%–100% cooling output) adapt to dynamic loads, improving energy efficiency by 30%.

- Fans: EC backward-curved fans auto-adjust airflow based on thermal load, operating below 65dB noise levels, with redundant designs for reliability.

- Smart Control System: Equipped with a 7-inch touchscreen for real-time monitoring of temperature/humidity trends and equipment status. Supports Modbus TCP/SNMP protocols for seamless DCIM integration, enabling remote alerts and fault diagnostics.

Selection and Deployment Guidelines

Key Metrics:

- Power density:

| ≤30kW/cabinet → Air cooling |

| 30–80kW/cabinet → DX liquid cooling |

| >80kW/cabinet → Immersion cooling |

- Climate:

| Hot/humid regions | Prioritize water cooling + free cooling. |

| Cold regions | Use low-temperature kits (e.g., SY Series supports -35°C operation). |

- Scalability: Reserve 20–30% cooling capacity for future compute growth (3–5-year horizon).

From Edge Rooms to Hyperscale Data Centers

Small-to-Medium Server Rooms & Industrial Applications

- Requirements: Space constraints, moderate power density (20–50kW), rapid deployment.

- Solution:

- Air-cooled precision AC (e.g., SYRC MA12 U/D, 12.5kW cooling capacity), supporting per-cabinet temperature control and installation on concrete floors (no raised flooring needed).

- Modular design allows phased expansion (e.g., initial deployment of 3x MA12 units, scalable to 5x units as demand grows), ideal for corporate IT labs or retail edge data centers.

Enterprise Data Centers & High-Density Computing

- Requirements: High power density (≥50kW per cabinet), 24/7 operation, stringent PUE targets.

- Solution:

- Hybrid liquid/air cooling: High-density zones use DX liquid cooling (e.g., SYRC DA Series, up to 122.9kW) with cold plates for direct GPU cooling, while low-density zones retain air cooling.

- Free cooling integration: In cold climates (e.g., Scandinavia), glycol-assisted free cooling reduces compressor runtime by >50%, achieving annual PUE as low as 1.15.